The current position:Home > News > >The correct cleaning method of ultrafine pulverizer

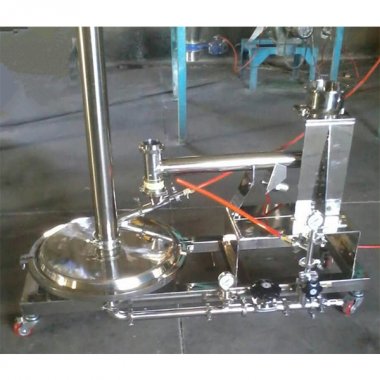

The correct cleaning method of ultrafine pulverizer

Ultrafine pulverizer in the end of the work needs to be cleaned, this can effectively increase the service life, the specific cleaning method is as follows:

For the ultrafine grinder the correct cleaning method can be divided into such two parts, the external and internal cleaning.

1, external cleaning: ultrafine grinder external, all for stainless steel, this is also a very important part of the machine, to its cleaning, only need to use a towel to wet, direct wipe can.

2, internal cleaning: inside the ultrafine grinder, there are crushing cavity and motor, this part of the cleaning is more complex, can not be directly washed with clean water, the need to use a clean towel, the dust inside, first wipe again, and then slightly wet the towel, for a detailed wipe. As long as at ordinary times pay more attention to the cleaning and cleaning of the ultra-fine pulverizer, so that not only can increase the life of the machine, but also can be used in peacetime, use more smoothly.

No matter what kind of machine, after it has been used for a period of time, whether it is the surface or the interior, it will be stained with dust, for such dust, although the machine temporarily caused not much damage, but a long time, over time, it is hard to say. Therefore, it is also necessary to clean the machine properly. Although the ultrafine crusher is used in many processing industries, and it is also used in some mines, used to break the ore, which in the processing itself, there will be a lot of dust. Many people will feel that there is no need to clean, in fact, this idea is wrong, if not cleaned, then in addition to the machine will break down, the life of the machine will also be affected to varying degrees.

So how do you clean it properly? As we all know, there are some machines that cannot be cleaned casually, especially the internal cleaning. If there is a little carelessness, it is likely to cause damage to the machine. In fact, ultrafine pulverizer, is the same reason, it is also the internal electrical appliances, and wire, if the direct water cleaning, then it is likely to make the motor and wire with water, so that the wire fire, the motor burn out.

The daily cleaning and cleaning of the ultrafine grinder shall be carried out by the mill crusher operator, technologist and workshop director. The operation method is as follows:

1. The ultramicrogrinder is directly in contact with the product, and its cleaning degree directly affects the quality of the drug. After the production, it should be thoroughly cleaned.

2. When the production is over, turn off the power and send all the materials in the production to the intermediate station according to the process of material entering and leaving the station.

3. Hang the equipment status card to be cleaned.

4. Open the crusher and move the bag, sieve and detachable air pipe into the sink of the cleaning room.

5. Pour about 2/3 of the volume of 30~40℃ warm water into the tank, soak it for 10-30 minutes, and then wash the front and back of the powder collecting bag repeatedly with running water until the powder collecting bag is clean; Clean the screen and air duct with a soft bristle brush to clarify the water solution. Rinse three times with ionized water. Dry in the same grade clean area as the crushing area. Set aside.

6. Dip a special clean cloth with warm water to wipe the material inlet, the inner cavity of the mill, the material outlet and the powder collecting room repeatedly until clean.

7. Clean the inner wall of the crusher, the powder conveying tube and the cyclone separator thoroughly with deionizing.

8. Dry the above parts with a clean dry towel and wipe them clean with 75% ethanol.

9. Wipe the operating room floor, power distribution cabinet, motor and operating cabinet clean.

10. After the bag and sieve are dry, install all parts of the crusher in the reverse order of disassembly.

11. Clean and flush the operation room until there is no dust or water on the ground.

12. Fill in clearance records.

In the previous:上一篇:Ultrafine crusher is an advanced crushing technology in Chin

The next article:下一篇:中药竞争优势的提升离不开制药粉碎机强助攻