The current position:Home > Shredder display > Drying mill > > Dry crushing machine >

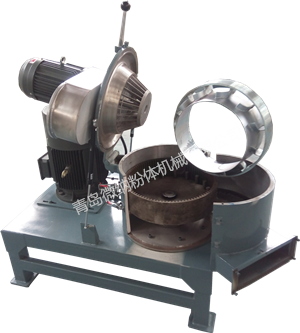

Dry crushing machine

Product introduction: 一、概述: 干燥、粉碎一体机-回转真空干燥机,在双锥真空干燥机的基础上,进行了改进及试验,采用两头增加粉碎装置;小型回转真空干燥机,可选用一头增加粉碎装置,可根据客户要求设

Product details

The rotary vacuum dryer, which is an all-in-one drying and crushing machine, is improved and tested on the basis of the double-cone vacuum dryer. Small rotary vacuum dryer, one end can be selected to add crushing device, can be designed according to customer requirements.

The double cone rotary vacuum dryer with crushing device can effectively prevent the material from agglomerating and forming in the drying process; The temperature inside the cone is controlled; By adding crushing device, the drying time of material is shortened. Does not damage the material characteristics; With the addition of crushing device, instead of the separate use of crushing machine, the products with aseptic requirements can be closed crushing and drying, drying and crushing can be completed in one machine, avoid secondary pollution, and can be directly packaged.

Ii. Working principle

Drying and crushing all-in-one machine, crushing device is installed at both sides of the cylinder body, crushing motor is placed outside the cylinder body. The cylinder body adopts jacket type. Steam or hot water can be fed into the jacket to heat the inner tank, which is conducted to the material for drying. The tank body is placed on both sides of the frame through the main shaft. Mechanical seals are installed at both ends of the spindle, one end is the interface of steam and condensed water, and the other end is the vacuum outlet. The vacuum pump or vacuum system makes the tank in a vacuum state, and the evaporated water vapor is removed in the drying process. The motor or reducer is also placed in the frame, and drives the positive and negative rotation of the tank through gear transmission, so that the material is constantly up and down, inside and outside turning. In the crushing process, the material does not agglomerate, more conducive to drying, can constantly change the heating surface, so that the material heated evenly, to achieve the purpose of balanced drying.

3. Equipment features

1. All-in-one drying and crushing machine, which simplifies the working procedure, reduces the loss and improves the product yield.

2. The shaft end adopts mechanical seal, other sealing points are equipped with double channel seal, and the sealing material is silicone rubber or fluorine rubber.

3, filter device, stainless steel wire mesh sintering or powder sintering plate, metal sintering plate.

4, tank can be positive and negative rotation, the speed is controlled by the inverter arbitrary adjustment

5, under the closed state operation, the product nondestructive leakage, no pollution, suitable for strong odor and toxic materials.

6, vacuum operation, at low temperature also has a high evaporation rate, especially suitable for heat sensitive materials and easy to oxidize materials drying, also suitable for materials containing solvents, and solvent recovery.

7. The equipment has compact structure, small floor space and easy operation.

8. Large amount of charging, charging coefficient up to 30% ~ 40%.

Iv. Application Scope:

Drying and crushing machine, suitable for medicine, chemical, food and other industries, for sterile products, microcrystal products, easy to agglomerate products more favorable.

In the previous:上一篇:没有了

The next article:下一篇:没有了